EXPOSING DEVELOPERS WHO FAIL TO APPRECIATE AND RESPECT COMMUNITY, ENVIRONMENT AND SPIRIT OF THE LAND

FOR MORE DETAILED INFORMATION ABOUT TREATED TIMBER ALSO SEE HEREMarch 2005 APVMA bans CCA timber for certain applications

June 29 2012: New Restrictions In Place For Arsenic Treated Timber

Treated pine decking. How many homes in Australia have this decking and how many Australians have been exposed to CCA by playing, lieing, standing and lounging on treated pine decks?

South Australian EPA Media Release 15 February 2006.

Auspine Limited convicted and fined over breach of licence

South East Company Auspine Limited has been convicted and fined $40,800 in the Environment, Resources and Development Court for contravening an EPA licence condition at their Kalangadooo timber presevation plant.

The maximum penalty for such an offence is $120,000.

The company pleaded guilty to not installing a roof over a concrete drip pad used for storing timber treated with Copper, Chrome and Arsenic.

The roof should have been constructed by 1 September 2004.

During rain events, the drip pad roof would reduce the amount of stormwater that becomes contaminated by excess chemicals being washed from the treated logs.

Her Honour Judge Cole in her remarks said there was no real expression of contrition on behalf of Auspine and there has been little effective action taken to comply with the licence condition.

EPA Chair and Chief Executive Dr Paul Vogel said the judgement sends a significant message to industry and the community that the EPA is acting as a responsible regulator.

This judgement also serves as a timely reminder to companies of their obligation under the EPA Act to take measures to protect the environment.

Timber Treatment Plant/CCA Disasters

| Armidale (NSW) | Tumut CSR (NSW) (1999) | |

| http://judgements.fedcourt.gov.au/1994/FD002150.htm (Federal Court ruling) | Ringwood (Vic) Spill (2000) | |

| Mordialloc (Vic) 1991 | Bossier City (Louisiana) (2001) | |

| Maryborough (Qld) | Kimbe (PNG) (2002) | |

| Mount Gambier CSR (SA) Spill (1995) | Coffs Harbour (NSW) (2003) | |

| Dartmoor CSR (Vic) Spill (1996) | Pemberton (WA) (2003) |

APVMA Review Recommendations (March 2005)

10.1 Label Directions

It is proposed that CCA labels be varied by:

i. requiring that timber treatment facilities be designed and operated to meet appropriate Australian Standards (AS/NZS 2843.1:2000 and AS/NZS 2843.2:2000).

ii. not permitting uses of CCA timber treatment products for timber intended for use as garden furniture, picnic tables, exterior seating, children's play equipment, patio and domestic decking, and handrails.

iii. specifying that CCA products may be used for preservative treatment of timber and timber products intended for the following end uses: piling and other structure foundations, residential construction, industrial and commercial construction, rura and farm use, fencing, poles, landscaping timbers, fresh and salt water structures, signage and boat construction.

iv. requiring each timber piece treated with CCA (except specific circumstances where supplied and therefore marked as a pack) to be legibly and durably marked (at least to the point of the first person who uses the treated timber) with a treating plant identification number, hazard class and chemical number, as well as the statement:

"TREATED WITH COPPER CHROME ARSENATE"

v. including more detailed instructions for application, mixing and vacuum/pressure operations, management of freshly treated timber, management of liquids, sludge or waste material containing CCA residues of wildlife, fish, crustaceans and the environment, and storage and disposal...

Treated pine stored in open at CCA plant Budgeree Central West Victoria.

Armidale (NSW) (Australia's worst CCA disaster?)

CCA Contaminated Site Housing Development at Martin Street Armidale

Summary: Residents of the Martin St housing development discovered they were living on a highly contaminated site in January 1990. After nearly four years of investigation, community lobbying, ongoing health problems and an extensive media campaign, a buy-out option was negotiated in late '93.

Author: Mariann Grinter

History: The Martin St Armidale site in northern New South Wales (NSW) was for many years a wood treatment plant using the Copper Chrome Arsenic process. It was subsequently rezoned and developed as housing estate in the late 1980's. Prior to the urban subdivision of Martin St, the Armidale papers had carried numerous reports of spills and accidents at the site. Both the Local Council and the then regional State Pollution Control Commission were aware of the history of the wood treatment plant. Yet, the Council approved the urban subdivision and 26 families bought land on the estate. The on site contamination became obvious when house piers were sunk into the ground and a black creosote-like ooze bubbled to the surface.

Sampling: After the initial discovery of the contamination in January 1990, surface soil sampling in April, detected levels of Arsenic up to 3800 ppm, Chrome at 1950 ppm and Copper at 1000 ppm. Also detected in 14 soil pit perimeter samples at the site were a number of polycyclic aromatic hydrocarbons (PAH) in the range of 14- 14,605 ppm (approx aver. 2,457 ppm). There was no question this was a highly contaminated site with levels far, far in excess of those considered safe for human health.

Health: Three and a half years later, little action had been taken, health effects were already apparent and no clean up had been carried out. The resident's blood showed the presence of copper, chromium, DDT and Arsenic (testing was not sufficient to accurately measure arsenic exposure). Health effects reported by the residents varied from severe contact dermatitis, respiratory problems, nosebleeds, visual damage, stomach aches, diarrea, breathing difficulties and skin disorders, behavioural disturbances in children.

The residents, still living on the contaminated site prepared for their court case in September '93 where they hoped to prove liability against Armidale Council.

The Federal Government's earlier promise of intervention in January 93, was realised when they introduced Sir Lawrence Street to negotiate between the parties. A buy-out option was agreed upon in late 93 and the majority of residents have moved from the estate.

It had taken approximately 3 years and 10 months to resolve the plight of innocent home-buyers who through no fault of their own purchased contaminated housing blocks.

Remediation is now being investigated.

References: Personnel correspondance with residents January 1991 - December 1993.

Selected quotes from Alec Finlayson Pty Ltd v. Armidale City Council and Basia Holdings Pty Ltd. (Federal Court of Australia (1994).

"1. ... the Council re-zoned certain land, formerly in an industrial zone, as residential land; subsequently granted development applications for subdivisions of the land for dwelling purposes ... the subdivisions were seriously contaminated with a combination of creosote (which contains polycyclic aromatic hydrocarbons, toxic organic compounds known as PAHs ...) and copper chrome arsenate ..."

"2. ... In 1967, a substantial area of land at Armidale, between a street known as Martin Street ... was zoned for industrial uses. That year, the Council approved plans for the building of structures on the land in order to accomodate the operation of a timber treatment plant in which telephone poles, and some other timber items ..., were to be impregnated with creosote ... The application was made by Arthur H. Hasell and Company Pty Ltd (Hasell)..."

"3. The focus of these plans, and of the intended activity, was a pressure cylinder 72 feet long, having an inside diameter of six feet ... It was to have hydraulically operated doors at each end, and was to be equipped with bogies to carry logs, poles or other pieces of timber into it, on rails, and out of it at the other end after impregntation. There was to be 140 feet of external track at each end of the pressure cylinder to carry the poles. Two creosote tanks, one of 10,000 gallons capacity and the other 12,000 gallons capacity, were to be provided ..."

"4. ... Council's final inspection took place on 7 June 1968 ... However, on 22 July 1968, the Council wrote to Hasell, referring to a visit by its officers that day, and advising 'it will be necessary to provide a creosote arrestor as stated in Council's building permit of 24th October, 1967 to prevent creosote from entering any water course or private lands'. On 22 August 1968, there was a conference ... Minutes of the meeting record that 'Mr Crawford (Council's Health and Building Inspector) spoke of the creosote finding its way onto a grassed area on the opposite side of the street, and the need to prevent a (recurrence)'; that 'a site inspection indicated that creosote spillage from either end ... of the cylinder was finding its way into the storm water system'; that further inspection showed 'surface water was mixing with creosote spillage', and that Hasell's representative 'indicated that there had been a considerable spillage of creosote as a result of an error when handling the impregnation equipment". It was agreed that 500 gallon concrete tanks were to be fitted to the surface water sumps, designed to enable creosote to be skimmed off the surfaces of the water in the tanks. The ground level was to be graded (plainly, it had not been concreted ...), and work was to be done at the southern end of the cylinder "to prevent surface water coming in contact with creosote laying (sic) under at the end of the cylinder".

"5. Unfortunately, either this work was not all carried out, or it proved inadequate. At a meeting of Council on 26 May 1969, a report was requested "concerning the escape of creosote". ... It indicated that in February 'creoste was finding its way to the creek ... this creek, known as Martin's Creek, was some two to three hundred metres away, and the original escape had been many months earlier. Undoubtedly, it must have been a major spillage ... On June 24, the creek had been found free of creosote."

"6. However, shortly after 14 August 1969, the Council received a letter of that date advising there was 'a pool of creosoty water in the unmade road ... east of Martin Street'. This was an unmade road which extended, from a point in Martin Street about opposite the treatment works, down the slope in the direction of the creek. ... A (Council) report followed on 22 September, which asserted that 'the waste disposal from the pole impregnation plant is continually under review and that further attempts are being made to prevent even the smallest quantity of creosote entering the main watercourse'. ..."

"7. But Council's file shows that the situation was not in fact rectified. There were complaints again, in August 1970, that whenever it rained 'creosote flowed into the creek'. An inspection by Mr Crawford on 16 September 1970 was noted as showing 'creosote oil not removed from pond since last told to do work'. Mr Crawford noted the presence of 'creosote in creek and globules remaining over surface". He specifically noted that Hasell was responsible."

"8. It was also in September 1970 that the question was raised of the proposed use in the plant of copper chrome arsenate, and Hasell was advised to make an application to Council."

"9. On 12 October 1970, Council again wrote to Hasell advising that '(c)reosote was entering the water course', and requiring pits and ponds to be cleared 'at least twice a week so that creosote does not enter the water course'."

"10. On 28 October 1970, the Council approved plans for the installation of two new tanks to contain Tanalith (described as copper chrome arsenic salt) ... the plans suggest that one of them was considerably larger than the larger of the creosote tanks. Council's approval was given subject to the condition that '(d)etails of the disposal of the excess water and salts (be) supplied to Council for approval'. The imposition of this condition gave rise to a letter from Hasell of 13 November 1970, in which it was stated: 'Excess water and salts will not pose any problems. This preservative is totally different to creosote in that it does not require heat, so no fumes are released, and it becomes fixed in the wood cells so it cannot 'run off' or leach out. The only free solution released is when the cylinder doors are opened and approximately 15 gallons runs out into the cylinder door sumps and is pumped back to the storage tank.' ..."

"11. In February 1971, an inspection of the pond on the other side of the road from the treatment works resulted in a letter from the Town Clerk to Hasell of 12 February 1971, which referred to 'a small quantity of creosote oil on the surface' and stated that 'maintenance was needed to the area' ... on 26 January 1971, the Medical Officer of Health of the New South Wales Department of Public Health at Tamworth had written to the Town Clerk referring to samples of water collected from Dumaresq Creek and Martins Gully on 8 April 1970 which, he said, 'were highly polluted by waste water discharged from the Armidale City Gas Works and Hasell's Timber Impregnation Works'. A government analyst's report had previously been forwarded to the Council. It should be pointed out that Martins Creek ... runs into Dumaresq Creek at a point some one to one and a half kilometres away. Dumaresq Creek is the major stream of the city of Armidale. Minutes of a meeting of a Council Committee include the recommendation 'that the Medical Officer of Health be advised that Hasell Impregnation Ltd intend to take legal action regarding their waste products and the Gasworks will cease making coal in six months time' ... Plainly, the problem was seen as still unsolved."

"12. On 16 March 1971, the Town Clerk wrote to Hasell indicating that no advice had been received, and stating that a 'recent inspection of the area revealed that insufficient maintenance was given to the collection of the creosote in the small ponding area'. ...

"13. An inspection report signed by Mr Crawford and dated 6 May 1971 states: 'Large pond opposite not given maintenance for some time. Creosote on surface to outlet. Old 44 gallon drum nearby - water dark brown to black'. The Town Clerk sent a letter to Hasell of 10 May 1971, referring to these and other matters, and directing Hasell 'to tidy up the area, maintain the premises to prevent creosote spillage ... '."

"14. In November 1972, Hasell (now under the control of Allen Taylor and Company Limited) applied for Council's approval to use an area of about eight acres, on the other side of Martin Street from the plant, as an "Air Seasoning yard" for hardwood poles. The application contained the statement: 'It is not proposed to store any treated timber on the area.' This application resulted in petitions being presented to Council, which were said (without denial) to be supported by 227 signatures, objecting to the expansion of the plant and referring (inter alia) to 'the seepage of industrial waste into Martins Gully, which eventually finds its way into Dumaresq Creek (as) a problem which should be of paramount importance'. The Council granted the development consent requested by the company, on 29 November 1972, 'for a period of two years'. In the event, the use simply continued for the life of the timber treatment works."

"15. On 14 May 1973, there was submitted to the Town Clerk a report of the Town Planner concerning a proposed Interim Development Order No. 2 (I.D.O. No.2). This report indicated that land including the site of the treatment works was being considered for re-zoning as residential land ... Consideration of I.D.O.No.2 dragged on for some time. On 16 April 1974 there was a meeting with a Mr Nichols, a representative of the State Planning Authority, attended by members of the Council and by Mr Hegarty, at which Mr Nichols stated (according to the minutes) that he 'considered that area for rezoning to residential from industrial in vicinity of Hassels (sic) Impregnation appeared not to be suitable for area ...' ...".

"16. On 1 October 1974, the then Minister for Planning and Environment of New South Wales issued a document entitled 'Principles and Procedures for Environmental Impact Assessment in New South Wales ...'"

"17. On 14 October 1974, the Council made formal application to the State Planning Authority of New South Wales, asking it to recommend to the Minister, for gazettal, the proposed new I.D.O. No. 2 for the City of Armidale, including the proposed change of zoning of land in the vicinity of Martin Street to residential. Minutes and reports which are in evidence show that this was regarded by the State Planning Authority as controversial in view of the existing industrial use. As at 28 February 1975, according to the documents, it was understood the land on the opposite side of Martin Street from the treatment works was being used 'for storage of treated poles', notwithstanding that permission to use this area had been based on an assurance the use would not use treated poles ... At a meeting of Council held on 21 April 1975, Mr Nichols 'explained to Council that careful consideration would have to be given to future consequences of rezoning area to residential in view of their future compatibility with residential development.' ..."

"19. On 22 April 1975, the Council wrote to the New South Wales Planning and Environment Commission, which by then had replaced the State Planning Authority, reaffirming its proposal to re-zone the land in question ... On 5 September 1975, I.D.O. No.2 was finally gazetted. As gazetted, the interim development order provided for the land in the vicinity of Martin Street to be included in a residential zoning ..."

"20. On 26 September 1975, there was forwarded to the Council a petition by residents of the area near the impregnation works, signed by a very large number of people, which referred to the 'smell which pervades our houses when the wind blows in our direction for if we ... leave our windows open our homes are impregnated and it is a very nauseating odour which also has an action on nose and throat', and as well to problems of noise and dust. The result was an inspection of the plant by Mr Crawford with a representative of the State Pollution Control Commission. The Commission wrote on 12 December 1975 to the Council. ... 'agreed that the odour emanating from the premises could be a nuisance at times to residents in the vicinity',and the letter added: 'Run-off from the premises drains into Dumaresq Creek through a waste water treatment system installed on the premises. However, the Commission is currently investigating the quality of this surface water emanating from the premises, and should it be found to be unsatisfactory, action will be taken by the Commission to ensure that the quality is upgraded to an acceptable standard.' ..."

"21. But on 13 December 1976, there was an escape, attributed by the Council's City Health and Building Surveyor, Mr Crawford, to vandalism, of about 3000 gallons of copper chrome arsenate. This occurred when the cylinder was opened after it had been about half filled with the solution by some person unknown. The doors could not be closed against the rush of such a large quantity of liquid, and it poured out, entered the drainage system, and heavily contaminated a section of Martins Creek ... pumping out of the pond across the road from the treatment works and disposal in the Council's waste disposal area. The top 18 inches of sediment left after the pumping out of the pond was also removed by backhoe and transported to the city dump."

"22. ... Mr ****, who did give evidence, insisted that the Tanalith did not flood the plant site, except perhaps to a minor extent, but flowed directly through the drainage system. I found it quite impossible to accept that evidence. It was directly opposed to an eye-witness account ... The drainage system was not designed to cope with a flow of 3,000 gallons from a cylinder of a diameter of six feet, and I am quite satisfied there must have been an extensive flow of the solution over the gravelled surface in the vicinity of the cylinder. Of course, it is plain that a very large quantity of the solution eventually found its way into the pond, and even into Martins Creek". (The Council failed to call upon their staff member who was most knowledgable of the spills).

"23. ... a minute of the State Pollution Control Commission dealing with the incident contains the statement: 'An inspection of the premises had been carried out by Mr *** (an officer of the Commission) approximately a week before the incident, as a result of which it was proposed to serve a notice under the Clean Waters Act on the Company to improve the drainage system'. It is apparent, therefore, that pollutants had in fact been continuing to escape prior to the disaster on 13 December 1976. Indeed there is no indication at all in the evidence that either the hope expressed by the Council in 1971 or the assurance it had given the petitioners on 11 February 1976 had ever been more than empty words".

"24. On 31 December 1976, the State Pollution Control Commission sent a formal notice to Hasell requiring it (inter alia) to do the following things:

a) Within 60 days of the date of this notice construct a bund around the impregntation and storage facilities, with a capacity to hold the total volume of treatment liquids stored on the premises. The bund shall be fitted with a pump well and shall not contain drainage valves. ...

d) Within 60 days of the date of this notice cease discharging wastes, other than uncontaminated stormwater, from your premises to nay waters."

Earth bunds were constructed in 1977 in response to this notice. It would appear that the completion of the bund walls probably effectively prevented further spillages escaping from the treatment works. However, there is nothing to suggest that the features of the operations which had produced these spillages in the past were remedied in any way, and the inference is that continuing spillages were absorbed in the treatment area, being unable to flow past the bund walls".

25. ... Evidence was also given at the hearing by a Mr. A.R. Bracken, now a security officer at the University of New England, who was employed by Hasell during the period from early in 1972 until May of 1977 ... For much of the time, he was employed as one of three fork-lift operators, but he also operated the pressure cylinder. He described the treated poles as "dripping" after they came out of the process, and as continuing to do so for a considerable time. ..., the area occupied by Hasell received a quantity of creosote as well as some Tanalith... He said also that when the doors of the cylinder were opened, the creosote or Tanalith would run out into little sumps at either end. It was not pumped back out of the sumps. As far as Mr bracken knew, the liquid used to seep out and ended up in the pond, which he described as a "little dam across the street".

26. Mr Bracken described the filling of the creosote storage tanks from tankers. Creosote was pumped from tanker to storage tank, and sometimes the pumping would continue after the tank was full so that there was an overflow. It was different with Tanalith, which used to come in 44 gallon drums in powder form. The drums were then lifted onto a platform, to be tipped into the mixing tank which contained water. Sometimes, Tanalith powder was spilled, particularly if there was a heavy breeze.

27. One of the jobs done by Mr Bracken, although it was also done by others, was the getting rid of waste creosote and Tanalith. The waste came from the cylinder. It was tipped into 44 gallon drums stored nearby. Mr Bracken described a process of washing the cylinder with detergent, when there was a change-over from use of creosote to use of Tanalith, and vice-versa. The sludge, when the drums were full, was picked up by a fork-lift and dumped elsewhere on the plant site. He personally used four or five different locations on the site where he frequently tipped out the drums, but he noticed that other workmen tipped drums elsewhere on the site as well as in the spots he used. Asked to mark the various areas on a plan, Mr Bracken said:

"It was rampant, you know, they used to tip out in various places here and there, just odd drums. I wouldn't say it was exactly tipped out in those five locations. There was different places where I used to get a drum when that area was mostly full, I used to just drop a drum in between wherever I could."

He used to drive in between the stacks of poles to tip drums. Eight or nine drums were used, and when were all full they were tipped, about three or four times a month. The drums usually contained both Tanalith and creosote. This went on throughout the time he worked at the plant. As he said "that is the only way they got rid of the liquid". Creosote was also cleaned from the pond across the road into 44 gallon drums.

28. Mr Bracken described how the logs which had been treated continued to drip. It depended somewhat on the species of timber. Blackbutt, in particular, absorbed a considerable quantity of liquid, and then dripped. He used to stack logs with the fork-lift. To do that, he might transport them several hundred yards across the site while they were still dripping. Some of the poles had holes in them, which would fill with liquid, and when the pole was turned during stacking the liquid would run out. Rain, of course, would also wash some of the liquid off it it had not completely dried. Mr Bracken said you would see the colouring around the stacks. The creosote was observable on the ground. From time to time, when the operation of the fork-lifts had made holes i the ground, truck loads of gravel would be spread over the inequalities to restore the working surface. This, of course, would result in the burying of creosote and copper chrome arsenate previously lying on or near the surface.

30. ... I think the most probable conclusion from this is that the creosote accumulated in the arrestors installed when the plant was originally commissioned was not skimmed off, and the result must have been that over a period of time they ceased to function effectively. That fact would help to explain why the pond or dam across the road was hardly ever free of creosote. It must also have received quantities of arsenic, which would have been less obvious. It is, indeed, not suggested that the arrestors, designed as they were upon the principle that creosote floats on the surface, would have been effective against arsenic contained in the water.

31. Mr Bracken was the workman who opened the southern door of the cylinder on the occasion when there was an escape of some 3,000 gallons of Tanalith. He said "it just gushed out" and "flooded the whole area". He described it as "an enourmous amount", the force of which almost knocked him over. Of course, if the statement in the contemporary records that the cylinder was "half fill(ed)" is correct, there would, as a matter of simple calculation have been over 6,000 gallons in it, and the figure of 3,000 gallons estimated as the quantity which escaped, despite Mr Bracken's eventually successful attempts to re-close the cylinder, does not seem to be exaggerated. Asked where the liquid escaped to, Mr Bracken said:

"Well, it went wherever the ground was level, I suppose, it just went all over the place, all that area there and up through, up along the cylinder, in through the workshop, over the road, in and around these poles. But they did not go up hill because there was a grade off the slope, it wouldn't have went up the slope."

32. ... It was demonstrated that in some areas the contamination was very heavy. On at least two of the allotments into which the site has now been divided, it has been found necessary to lay a membrane in the soil in an attempt to contain the contaminants. After rain, a creosote scum has been observed on the surface of the ground. The odour of creosote has given a resident headaches, and caused other residents and visitors to the area to complain of the "terrible" smell of a burning sensation in the back of the nose. Digging, on one lot in particular, revealed significant quantities of visible creosote.

33 ... Contamination of the site is patchy, and is particularly heavy at various places in the vicinity of where the cylinder was, and where it is assumed sumps were located. There are also patches of contamination corresponding with areas where the dumping of the contents of 44 gallon drums filled with waste creosote and Tanalith may have occurred. It is probable that some of these patches of contamination were in fact caused in this way. Arsenic and PAH are present, in the main, in the upper layer of gravelly ground, which could have been removed and replaced before the land was subdivided. Once houses were erected, the problem was magnified. Arsenic and PAH are carcinogenic as well as toxic, and where both are involved there may be a synergistic effect, presenting a particular hazard in areas in which young children may play. It is known that some young children eat significant quantities of dirt (the phenomenon has a name - it is called pica, from the Latin word for a magpie); young children generally absorb dirt to an extent which was estimated in one scientific paper tendered in evidence at 100 mg. per day (but an elaborate study by John K. Hawley, of the Bureau of Toxic Substance Assessment, New York State Department of Health, put the figure at 160 mg. per day for children aged 2 1/2 years - and that is in the harsh climate of New York, where children might be expected to be outdoors less than in Australia; and vegetables grown in backyard gardens may take up substances from the soil. Of course, in sufficient quantities, pollutants may inhibit the growth of plants, and there was evidence that in some of the areas in question here grass and trees would not grow, or the grass was patchy and the trees were stunted. ... there is evidence that turning over the soil has revealed visible creosote, and the offensive smell of creosote has invaded homes on the land. One of the problems for any remediation is that the contamination varies greatly in intensity from spot to spot, so without removal of the entire upper layer of the ground in the area, it would be difficult to be confident that strong concentrations of PAH or arsenic or both had not been bypassed...

34 ... a careful Town Planner, who had ascertained those facts, would not have permitted the development of any of the land in question in this case for residential purposes without prior investigation and remediation. He would have borne in mind that children wander throughout the vicinity of their homes, so as to be exposed to contaminants on neighbouring properties and in parks; and therefore remediation could not properly be delayed until after the subdivision, when work on one part of the area could be rendered useless because similar work had not been done elsewhere.

35. At some stage in or shortly after 1979 or 1980, the timber treatment works was relocated in a different area of Armidale, and the operations which had been carried on upon the site since 1968 came to an end. On 29 October 1982, the land was conveyed for a consideration of $65,000 to the second respondent, Basia Holdings Pty Ltd. On 3 May 1983, permission was sought of the council for the use of the land as an overnight truck storage depot. Consent was granted on 14 July 1983, apparently on the basis that the application conformed with an existing industrial use. The documentary evidence suggests that, at the time, re-zoning for light industrial purposes was under serious contemplation.

36. Then, on 4 July 1984, after some discussions with officers of the Council in the early part of that year, Basia Holdings Pty Ltd submitted a development application, under s. 77(3) of the Environmental Planning and Assessment Act 1979 (NSW), in relation to the land being the former site of the timber treatment works. The development for which consent was sought was described as: "Subdivision into 9 Lots of (sic - scilicet as) part of an overall proposal to subdivide the property." The proposed development was described in an accompanying document, submitted by a consulting surveyor on behalf of the company Basia Holdings Pty Ltd as a "STATEMENT OF ENVIRONMENTAL EFFECTS", as providing "a residential area for 40 home sites together with an internal roading system and a Public Park." It was stated: "The soil appears to be a clay based and through previous industrial use has nearly a full cover of consolidated gravel. There are no unique features associated with the land and there has been no known reserve of minerals." The surveyor also stated, under the heading "Engineering" "The land is considered physically suitable for residential living. ... Drainage will be out of the subdivision and into the natural watercourse of Martin Gully and there will be no detrimental effect to other properties." ...

38. On 23 October 1985, Basia Holdings Pty Ltd sold to the applicant the residue of the land which was the former plant site ...

39. A further development application was lodged on 31 October 1985, referring to the earlier approval, and seeking devlopment approval for the second stage of the subdivision. Again no objection was raised by any department of the Council ... Development consent was given on 29 November 1985, and notified on 4 December 1985, for what was described as "the 27 lot subdivision ... nor ... , was there any mention of any problem of contamination of the site or possible contamination of the site by creosote or Tanalith.

40. In very general terms, the nature of the previous use of the land, including the fact that it had involved the application of creosote to timber, was known to the director of the applicant, ***, but the details were not known to him, and he had no reason to suspect that the site itself had been contaminated. Development of this land for residential purposes had already been the subject of final development approval, so far as the nine lots of the first stage, which fronted Martin Street, were concerned, and tacitly the development of the whole area, subject to a suitable subdivisional plan, had already been approved, before *** was introduced to the site...

41. Following the approval of the second development application, the plan of subdivision was also approved, and it was registered on 9 December 1985. Thereafter, settlement of the purchase of the land took place on 3 February 1986. Subdivisional works proceeded during the latter half of the year and into the following year, their completion to the Council's satisfaction being notified by it on 15 April 1987.

42. On 27 November 1987, the applicant made a further development application to re-subdivide lot 14 of the subdivision so as to create new lots 14 and 26. This was approved on 15 December 1987.

43. On 22 October 1987, the applicant had contracted to purchase what was in the evidence "the East Martin Street property" for a price of $48,000. This was the property on the other side of Martin Street, which had been used for the drying of poles during part of the period of operation of the treatment works. Settlement of this contract took place on 26 June 1988. The land was bought for the purpose of further residential development.

44. The applicant constructed and sold homes on three of the lots in the first stage of the 27 lot subdivision. The sales of these three lots all took place in the period April to July 1988. Other lots in the first stage of the subdivision were sold as land, and building contracts were entered into in respect of the construction of housing upon ten of the lots. On 21 September1988, a development was approved to subdivide lot 22 into two building blocks which became known as lots 30 and 40. From about October 1988, the applicant commenced selling blocks of land in the second stage of the 27 lot subdivision. Seven of the 12 lots were sold. The applicant has been unable to sell the balance of the blocks.

45. During the period between 6 September 1988 and 20 February 1989, the applicant purchased a further five lots from Basia Holdings Pty Ltd, being lots 1,2,5,6 and 7 of the first stage of the subdivision which had been carried out by Basia Holdings Pty Ltd. Four of these lots were resold. Three duplexes and a house were built on them under contract by the applicant.

46. Mr Finlayson, the applicant's director, first became aware of the site of the former treatment works was affected by contamination in February 1990, when a statement was made on television by the Mayor of Armidale. On 1 March 1990, a letter was received from the Council stating that, in order to determine the extent of the contamination, soil sampling would have to be undertaken at one of the lots. The applicant authorized this to be done, and it also terminated a building contract on which it had expended approximately $8,000 entering into a fresh contract with the client to build an identical residential building elsewhere.

47. During the hearing, there was admitted into evidence a formal admission by the Council, expressed in the following terms:

"Subject to the reservation in paragraph 4 below Armidale City Council, for the purposes of the determination of the proceedings, (other than the matters the subject of the orders for seperate determination - the damages questions) admits:

1. That at all times since 1 January 1973 some of the parcels of land referred to in the Schedule below were potentially contaminated with PAH's (sic) from creosote and arsenic from CCA levels that -

(a) exceeded background levels;

(b) required some action - either of investigation, evaluation, or remediation - in connection with any residential use of the land.

2. That at the time of the subdivision applications in 1984 and 1985 some of the parcels of land in the Schedule that were the subject of the residential subdivisions were in fact contaminated with PAH's from creosote and arsenic from CCA at levels that -

(a) required some action - either of investigation, evaluation, or remediation - in connection with any residential use of the land,

(b) would have been discoverable at the time.

3. The Armidale City Council admits that, if the issues of duty and breach are determined against it, the admissions in 1 and 2 above are insufficient to establish that Alec Finlayson Pty Ltd suffered some damage sufficient to complete a cause of action.

4. The Armidale City Council reserves -

(a) its denial of the existence of any relevant duty of care owed by it to Alec Finlayson Pty Ltd in respect of the loss claimed;

(b) its ability to contend that any failures by it to consider the potential contamination of the land was not a breach of nay such duty of care; and

(c) its denial of any reliance by Alec Finlayson upon either, any action taken by the Council, or any omission or inaction by the Council...

49. ... the is powerful circumstantial evidence to show that the Council, through its officers, was well aware of the contamination of the site ... and that those officers simply failed to apply their minds to the question whether the contamination ought to be investigated, in order to ascertain its extent and to determine whether it required remediation. Time and time again, the Council had received complaints about pollutants emanating from the site. At meetings of the Council ... detailing the consequences for the land and waters, up to a kilometre and a half away, of the spread of creosote and copper chrome arsenate from the treatment works. It is not believable that the Council's officers thought the pollution only began outside the boundary of the land. Unfortunately, it is all too believable that they gave no consideration to its implications in relation to the site itself, since, over a period of many years, they did nothing effective about its implications for the adjoining land, the residential environment, Martins Creek and Dumaresq Creek.

50. My conclusion that no serious attempt was made to remedy the situation is supported by a number of considerations. First, the fact is that the pollution went on for years until the State Pollution Control Commission (SPCC) issued a directive; it then ceased in respect of the area outside the site, so far as the evidence goes, immediately and permanently. In other words, effective measures were perfectly possible. The bund which the SPCC required the operator to construct was a simple and obvious measure. Secondly, there is no indication in the Council's own documents which were tendered in evidence that anything was done during the previous years to insist that the situation be truly remedied. The picture presented by the Council's own documents is of a series of defensive reactions to complaints. Assurances were given, but were not followed up. The continuous pollution of the pond across the road from the treatment works demonstrated that something was wrong, but not only was it allowed to go on for years; more significantly, there is no indication from the Council's records of a serious attempt to ensure that the problem was actually remedied, rather than palliated... Thirdly, the Council was made unmistakably aware of the serious potentialities of the operations carried upon the site on at least two occasions when very major spillages of, in the first case, creosote, and, in the second case, copper chrome arsenate, occurred.

51. As a matter of inference from these circumstances, and in the light of the evidence which provides their setting, it seems to me overwhelmingly probable that the officers of the Council knew that the substances used in the treatment of the poles and other timber regularly escaped from the supposedly closed system involving the cylinder; they knew that the operations were not being conducted with appropriate care to avoid the escape of contaminants; and they knew that waste materials were disposed of on the site. As to the last matter, the evidence is that Hasell was instructed by Mr Crawford to skim off creosote from the pond regularly, and that it in fact did so from time to time. The scum of creosote and water must have been disposed of somewhere. Similarly, the sumps were designed to be skimmed off. It must have been obvious that either the scum from the sumps also required to be disposed of or,

TO BE CONTINUED

Mordialloc (Vic) 1991

Mordialloc/Chelsea News April 16, 1991

Page 1: EPA terrorises us: timber firm by Melissa Cranwell

A Mordialloc timber treatments company claims an EPA order to clean its premises is an example of the State Government 'terrorising industry'.

The EPA served a clean-up notice on Timber Protim Treatment on April 5 after soil samples taken at the site in February revealed contamination.

The two samples were taken at the Governor Road site after a complaint that CCA was flowing from the plant on to Governor Rd, but a company spokesperson said there was no CCA on the site.

The contaminants identified by the EPA were liquid petroleum hydrocarbons and pentachlophenol.

The spokesman said he could not understand why contaminants had been detected because the Protim plant was "leakproof".

The only explantations for the find, he said were:

-sabtotage (someone intentionally pouring chemicals on the site);

-someone disposing of a small amount of residue in the garden area near the plant, or;

-A plant leak during past operations "but these seem highly unlikely", he said.

"The EPA are not serving the community by doing this. They are just sensationalising rather than trying to work with us" he said.

He regarded the EPA approach as one of "terrorising industry".

With the EPA order came a $290 invoice for the preperation and enforcement of the notice - an invoice the company refuses to pay.

The company spokesman said the company had not asked the EPA to investigate the site and while Timber Protim Treatment would comply with the clean-up order it was not prepared to pay the EPA's costs as well as its own.

The Protim plant treats radiata pine from Australian solar plantations to make it suitable for use. This is an alternative to using imported timber from tropical rainforests.

The company, which has been in Mordialloc for more than 40 years has already complied with part of the EPA order to employ environment consultants to prepare a full report on the area concerned.

The clean-up order to the company said "'environmentally hazardous substances' had been found on your premises. Your premises has been listed on the authority's register of contaminated sites," the order said. "Removal of your site from the register will depend on a satisfactory investigation - clean-up report.

Mount Gambier (1995)

More Details of this event coming soon.

Border Watch 10 March 1995 CSR acting on new EPA directives

Works are continuing at CSR Softwood’s Mount Gambier plant to comply with requirements handed down by the Environment Protection Authority after a hazardous chemical spill.

At the same time, the company is negotiating with the EPA as to how to meet the requirements within imposed deadlines.

A quantity of 2.7 percent copper chrome arsenate solution escaped into groundwater when more than 15,000 litres of the liquid was spilled from a storage cylinder at CSR Softwoods. The chemical found its way underground via a drainage bore on the site.

The EPA consequently issued a notice to CSR Softwoods under the Water Resources Act to take measures to ensure this sort of spill could not happen again. The company was directed to convert the drainage bore to a production bore.

Also, it was required to srill a series of observation bores near the drainage bore to monitor groundwater contamination.

Further, the company was directed to construct bunding sufficient to contain 120 percent of the capacity of the 65,000 litre CCA storage cylinder. An existing sump beneath the cylinder can contain around 30,000 litres. The drainage bore has now been converted to a production bore and is operational pumping groundwater from the area where the contamination occurred.

CSR Softwoods, Regional Manager, Mr Bill Howley, said from Melbourne that testing from this bore would continue, but he did not have results on hand. He emphasised groundwater testing had been going on at the plant for five years. “It has not started with this spill.”

A replacement drainage bore has been drilled about 100 metres north-west of the other one and is expected to be operational from today. The EPA has instructed the company to drill the required observation bores by March 15.

Meantime, new bunding is still in the planning stage. Mr Howley said this would be a significant project, but not huge, and he did not yet have final costings. “We’re going ahead and trying to get it completed within very tight time constraints,” he said.

Negotiations were continuing with the EPA as to meeting a March 30 deadline. Mr Howley pointed out that “previous arrangements” at the site did meet existing regulations. “What’s being asked are significantly increased requirements to help provide greater protection of the underground water in the area,” he said.

These requirements fell in line with draft standards for all timber treatment plants in Australian and New Zealand. “We are trying to co-operate fully with these people,” Mr Howley said.

TO: Minister for the Environment and Natural Resources

FROM: Senior Water Quality Officer, OEPA

SUBJECT: Question without notice in the Legislative Council about the CCA spill in Mt Gambier at CSR Softwoods

DATE: 14 March 1995. THROUGH: Manager, Monitoring and wastewater, OEPA Executive Director, OEPA Chief Executive, DENR The attached reply is suggested to the Parliamentary Question Without Notice (QWN 29/95) asked by Hon. Terry Roberts, Member of the Legislative Council and Opposition spokesman for the Environment and Natural Resources on 8 March 1995.

Question

What changes has CSR made to its current work and confinement practices at the discharging and holding areas for dangerous chemicals that it uses; and will it make sure that such a spill will not occur again?

Suggested answer

Softwoods Holdings Ltd, trading as CSR Softwoods, was issued a Notice under Sections 55 and 56 of the Water Resources Act on 1 March 1995 requiring the following range of clean-up and prevention actions at their timber treatment plant on Millicent Road, Mt Gambier:

*convert the drainage bore which allowed up to several thousand litres of CCA to accidently spill into the unconfined groundwater aquifer, into a bore to be used as a source of water for making up the CCA solution to process strength for timber treatment (this was aimed at ongoing extraction of groundwater which could be contaminated with CCA);

*establish bunding around the existing CCA pressure cylinder to provide 120% containment capacity, excluding any sludge volume which may accumulate within the bunded area from time to time (this was aimed at avoiding groundwater pollution problems caused by any similar accidents at the site in future);

*ensuring that any vehicle travelling into and around the drip pad area, where timber is allowed to stand for three days immediately after treatment with CCA, does not lead to ongoing contamination of other areas on the site (it is likely that vehicles with CCA contaminated tyres have caused small ongoing quantities of CCA to be transported to other areas where rainfall and runoff to drainage bores has lead to elevated levels of copper, chromium and arsenic in groundwater monitoring bores on the site).

In addition, the company has been asked to investigate the nature of cavities in the limestone walls of drainage bores located near the CCA pressure cylinder to help determine where further observation bores should be drilled to allow sampling of groundwater which has been potentially contaminated by the CCA spill on 22 February 1995, and to undertake sampling and analysis of water in the new bores for copper, chromium and arsenic according to sampling frequencies recommended by the Office of the Environment Protection Authority.

Following the commencement of the Environment Protection Act in May this year the company will also be required through licencing under the new Act to undertake ongoing monitoring of groundwater underneath the site and perform such improvements in the design and management of their CCA timber treatment process as necessary to ensure that rainfall draining off the site into the groundwater system is producing water with CCA concentrations no higher than drinking water standards.

Question

What potential for damage is there to both the confined and unconfined aquifer in the area?

Suggested answer

The Softwoods Holdings Ltd site, like most parts of Mt Gambier, is directly underlain by soil and sedimentary strata which allow for ready movement of rainfall and runoff into subsurface layers and ultimately the unconfined aquifer.

Therefore, it is susceptible to contamination from accidental chemical spills and industrial sites, stormwater runoff from roads and other hard areas, and general percolation of rainwater carrying pollutants from soil surface to subsurface into the aquifer.

The unconfined aquifer which occurs at much deeper levels below ground is not susceptible to pollution from these types of sources in Mt Gambier because it is overlain by a blanket of clay and other material which does not allow for ready downward leakage of water from the unconfined aquifer.

The CCA spill at Softwood Holdings Ltd discharged into a drainage bore containing karstic features which allowed for ready movement of the CCA into underground cave systems.

This has made recovery of the CCA and monitoring of its impact on groundwater quality difficult. However, due to vast quantity of water present in the unconfined aquifer the rate of dilution will be very great. The likelihood of groundwater below the site eventually reaching Blue Lake and the travel time for any copper, chromium and arsenic contamination to get into the lake is very difficult to predict due to the complex nature of the hydrogeology of the area.

Overseas research and water monitoring in the Mt Gambier region indicates that:

*the copper in CCA is unlikely to migrate far in groundwater due to the formation of chemical complexes with organic matter in stormwater and carbonates in limestone;

*chromium in CCA is likely to be quite mobile in groundwater; and

*arsenic in CCA is quite mobile but some forms may be absorbed and/or form chemical complexes with organic matter and a wide range of materials in clay and limestone.

Softwood Holdings Ltd has been monitoring groundwater quality, including copper, chromium and arsenic concentrations, for five years at various locations around their site and, as indicated in my answer to the previous question, will be required to intensify the monitoring in the vicinity of the bore where CCA was accidently discharged on 22 February 1995.

Industrial chemicals such as CCA have never been detected in the Blue Lake. This may be ascribed to the high dilution and/or natural chemical attentuation processes which I have briefly outlined. However, there is no room for complacency about the potential for pollution of the Blue Lake and the unconfined aquifer in general. Groundwater monitoring at specific industrial sites in Mt Gambier, across the unconfined aquifer within the region and in Blue Lake itself will be continued by this government and where necessary remediation will take place or alternative water supplies arranged.

Border Watch p3 21 March 1995 Extensive cave network has cavities... UNDERGROUND WATER THREAT

The timber treatment chemical spilled at CSR Softwoods last month could have escaped rapidly into underground caves, according to the Environment Protection Authority.

The EPA’s Emergency Response Co-ordinator Phil Hazel, said video cameras in several drainage bores at the site had revealed an extensive underground cave system. He said a large number of cavaties were found in the walls of the bore believed to have carried several thousand litres of copper chrome arsenate solution to groundwater.

This happened in an accident, on February 22, when more than 15,000 litres of the liquid were spilled from a storage tank at CSR Softwood’s Lakeside plant. The company began pumping water from the bore that night, but within 30 minutes it had run dry, with sediment plugging the hole.

Mr Hazel said holes had been found just above the level where the sediment was. This gave the impression that the chemical had escaped into the cave system and into groundwater, and could already be remote from the entry point.

Mr Hazel believed the CCA had probably moved north-west and south-east from the bore hole, as this was the direction the cave system ran. He said three or four more “observation bores” would be drilled for an accurate assessment of the cave system and to show the level of groundwater contamination.

“It’s thought that the CCA went down the hole and spilled into the cave system quite rapidly,” Mr Hazel said.

“We are trying to investigate the impact on the groundwater in the cave system.”

The drilling of the observation bores is being co-ordinated by Mr Jeff Lawson of the Department of Mines and Energy in Mount Gambier.

Meantime, CSR Softwoods is likely to spend more than $50,000 to meet bunding requirements handed down by the EPA. “The company is having to spend a fair amount of money,” Mr Hazel said.

“They told me $50,000 or more, and were having to reassess their entire CCA timber treatment process at that site.”

The EPA issued a notice to CSR Softwoods last month, under the Water Resources Act, to take certain measures to ensure this type of spill would not happen again. One of the requirements was to install bunding sufficient to contain 120 percent of the capacity of the 65,000 litre CCA storage cylinder. An existing sump beneath the cylinder can contain around 30,000 litres. Mr Hazel said he understood CSR Softwoods was looking at options for spending “a bit more” than $50,000 and upgrading to a more modern facility. He explained the company currently had limited space near the CCA cylinder for treated timber to dry on a drip pad.

After three days, the timber was being moved to another site for the chemical to fix properly. An investigation continues into whether the State Government should take legal action against CSR Softwoods for breach of the Water Resources Act. Mr Hazel said Mr Richard Talbot, from the Attorney-General’s Department, had been interviewing a number of people about the chemical spill’s impact on the groundwater.

These included CSR Softwoods staff, and personnel from the Department of Mines and Energy and Environment and Natural Resources. Mr Hazel said it would probably take three months to assess whether the government would pursue any court action. Mr Talbot would undertake primary assessment of the evidence, to go to the Crown Solicitor’s office.

Anonymous letter written to Executive Director of the EPA, Mr. R. Thomas. 10/3/95

Dear Mr Thomas,

I write to express my personal concern about the recent spill of CCA solution at the CSR Softwoods, Lakeside Mill.Rather I should say, concern that the circumstances should have made this possible.

I realise the EPA is set upon a lengthy and detailed program aimed at improved care and responsibility through requirements for E.I.P’s etc and good though that this is, I cannot accept an incident such as that should ever have happened.

Having spent much of my work life about that and many other mills I can say ‘normal', good management would have prevented such a serious spill. I am puzzled why your inspectors and CSR have never made sure bunding beneath cylinders or stock tanks is equal to containing full loads of the cylinders/tanks or that plant maintenance and operating procedures were adequate enough to prevent spills from going into public drains.

The ABC television and press reports, pardon me saying so, give a distinct impression that there is sympathy to CSR by the EPA and this ‘unfortunate’ incident was an accident not worthy of penalty.

Given the ability and knowledge CSR and other like companies have from years of running such plants, it is absolutely inexcusable for them to lose control and pollute like that.

Equally, such offenders should not be given opportunity to shelter behind an EPA busy with (much welcome) reforms. There are still laws in force and there are others like me now waiting to see application of these laws to such offenders.

Yours Faithfully

For information regarding potential impacts on Mount Gambier's drinking water supply click here.

Wood Treatment Facility Contaminates Louisiana Community

According to a September 5, 2001 report by the Environment News Service (ENS), Bossier City, Louisiana, home of the former Lincoln Creosote Plant, has some of the highest levels of chemical contamination, cancers and birth defects ever documented in the United States.

ENS reports that the Lincoln Creosote plant is now a Superfund site on the National Priorities List of the most hazardous sites in the country.

Like many wood treatment facilities, it was operated adjacent to a residential area, exposing hundreds of people to toxic chemicals. During its 30+ years of operation, the plant produced telephone poles and railroad ties, treated with creosote, copper-chromium arsenate (CCA) and pentachlorophenol (PCP). Neighbours of the plant believe their health problems, including sterility, birth defects and several forms of cancer, are a direct result of the wood treatment facility.

Others argue that these diseases are merely chance, or the result of bad genes. However, Dr. Patricia Williams, a medical professor from Louisiana State University found that the incidence of leukemia in Bossier City from the late 1970s to the mid-1990s is as much as 40 times higher than normal populations. She also discovered that incidences of birth defects are 300 percent higher that those recorded during a comparable time period in Osaka, Japan, the site where the U.S. dropped an atomic bomb during World War II.

Although a lawsuit involving 2,100 current and former residents was settled out of court with Lincoln Creosote last year, many of the plaintiffs were disappointed because they received no funds for future medical monitoring expenses and no compensation for their children and grandchildren who suffer from secondary exposure, reported ENS.

Bossier City resident Michael Davis, who worries about his daughter Brittany who started menstruating at age six and still suffers from growth hormone deficiency, asks, "Why was consideration not given to children not living at the site but bearing the weight of the effects?" Beyond Pesticides has published two reports on the health risks linked to exposure to CCA, penta and creosote.

Poison Poles examines the toxic trail left by these chemicals through manufacture, use and disposal. Pole Pollution focuses on EPA's health risk of penta. Both reports are available on Beyond Pesticides' website. http://www.beyondpesticides.org/

“The company, Hyne & Son currently operate a treatment facility at Granville, Maryborough. Some time ago they had a 7,000 litre spill at that site and have placed signs in the adjacent block saying do not enter, Environmentally Controlled Site. A more appropriate notice would read, Environmental disaster. The neighbours bore, across the road, has green water coming out of the taps. A house block down below the Environmentally Controlled Site is known to be contaminated. The Granville plant is located at approximately Latitude (South) 25E32'53" and Longitude 152E43'0".

Dartmoor Background: Applied for licence in June 1973. Licence issued by EPA (Licence Holder "Dartmoor Properties" . . . July 1976 - EPA inspects premises at Dartmoor. Discovered company using CCA treated shavings in boiler fuel. EPA pointed out breach in licence. " During our inspection we noted that the emissions from the boiler were a little darker... When asked what fuel was being used in the boiler, **** said bark, sawdust and some treated shavings. **** and myself quickly pointed out to **** that the use of CCA treated shavings as boiler fuel was not permitted, and was in breach of Schedule A condition of the companies licence. **** said that there will be no more burning of treated shavings, as the parent company in Mount Gambier is going to use the treated shavings in the manufacture of particle board". 8Dec 1977 - Company applied for transfer of licence from old company name (Dartmoor Properties Pty Ltd) to new name "Softwoods Dartmoor Limited". Dec 1980 - Schedule B licence inspection carried out. Plant - 3 cyclone systems and one wood-fired boiler. Wood waste sent to S. Australia for board manufacture. Dec 1984 - EPA issues draft amended licence (19/12/84). Amended licence includes emissions to land. Some objections from Shire of Portland to disposal to land. May 1987 - Complaint (resident, Dartmoor) re: black soot from boiler stack at pine mill. Long running problem. July 1987 - Complaint (employee, pine mill) re: soot and particulates from boiler. August 1987 - Inspection of premises. Complaints substantiated by photos of soot on pool cover etc. *** pointed out non-compliance with licence conditions 10 and 11. Matter discussed with Softwoods P/L and complainant (employee). Sept 1987 - EPA sends letters to Softwoods, requesting action (within 21 days) re: complaint of soot/particles. Oct 1987 - Softwoods reply to EPA with plans for modifications (prepared by "Steam Research and Development Service". CSR go ahead with work/upgrade.

On 28th October 1996, a leak in the base of the 2.5% copper chrome arsenate (CCA) storage tank was discovered. Suspicion of the tank was raised when a loss of 6,000 L of CCA was recorded over the weekend (26-27 October 1996), no prior loss of CCA from the tank was evident. On the morning of the 28th October a loss rate of 150L/hr was recorded. The tank was promptly emptied, cleaned and inspected, an estimated 6-7,000 L of 2.5% CCA solution was lost overall. The tank consists of a cylinder, approximately 5 m in length and 4 m diameter, which is buried vertically (ie the base of the tank is 5 m below ground level) with the top end open. The leak occurred in the floor of the tank and appears to be the result of corrosion.

CCA Leak Dartmoor (from EPA FoI Request)

Dartmoor - Victoria. The GTFP timber mill which was the site of a toxic leak occurring in 1996 when the mill was under the management of CSR. 8000 litres leaked from a storage cylinder into groundwater. Fears were held that the towns water supply would be contaminated. Note wafting smoke from chimney at the mill. In the past CCA sawdust and scrap wood was burnt in furnaces at the mill.

31 Oct 1996 - Melbourne 3LO Peter Couchman 8.41AM interview with Dr Graham Rouch, Victoria's Chief Health Officer, regarding possible contamination of Dartmoor's water supply.

Peter Couchman: . . . Well, we've got news this morning of an apparent serious contamination of the water supply at Dartmoor in the south-west of Victoria . . . But the residents there were letterboxed by the Department of Health yesterday afternoon warning them that they shouldn't use water from the town supply, or even the Glenelg River at Dartmoor for drinking, cooking, bathing or even gardening.

Now, the notices handed out by the health department say that it believes the water supply may have been contaminated by a poisonous solution of copper chrome arsenate. The local council, I understand, is trucking in water today to the residents. But there appears to be a connection here with the disappearance of more than six thousand litres of copper chrome arsenate from an underground storage tank in the CSR timber treatment plant at Dartmoor . . .

Couchman: How do you lose six thousand litres of copper chrome arsenate?

Rouch: Well, this was from an underground storage tank that has apparanetly sprung a leak . . . this quantity has gone missing and is assumed to have leaked into the ground . . . We have here a problem of uncertainty rather than an actual demonstrable hazard to people, and I'm afraid that uncertainty may not be easily resolved in the short term.

Couchman: Why, because the tests will take some time?

Rouch: Well, we may well find the water supply clear today - I hope that is the case - but we can't say where or how this material is travelling underground. Everything depends on the particularities of the geological formation.

Couchman: So I take it then that you're working on the assumption that this six thousand litres of copper chrome arsenate has leached into the underground system, may take some time to find its way through to goodness knows where; so that you'll have to keep a watch and ... probably people will not be able to use their water supply in Dartmoor for many, many months.

Rouch: Well, we can't answer that just yet. There will be immediately drills. . . bores drilled in the vicinity of the tanks to determine where the material has gone, at what level and where it may be moving; but I can't imagine that we're going to get immediate answers that'll give us a high probability at this stage.

Couchman: OK. Can you tell me more about these underground tanks that are containing this poisonous solution?

Rouch: Well, I can't really. These seem to have been in place for many years, so obviously this is a recent phenomenon of a pinhole or something of that sort that's developed in one of the tanks.

Couchman: ... are these tanks checked and inspected on a regular basis?

Rouch: Well, I can't answer that. We are dealing here with our collegues in the Environment Protection Authority, and these matters you really will have to put to them.

Couchman: ... is a planning permit issued for an underground storage of potentially... well, not just potentially, but of a poison... highly poisonous and toxic solution like this?

Rouch: Well, obviously that's again a question you'll have to put to the EPA. Our concern at the moment is that we really have to find out if there is a genuine risk to the water supply. There is obviously a fair degree of distance in terms of depth between the two. This artesian supply is at some ninety metres, for the town. But ...and the stratum might be well sealed off. But these are all uncertainties that may be difficult to resolve in the short term...

1/11/96 - CCA Leak Dartmoor

1. Softwood Holdings a CSR subsidiary (CSR) operates a timber preservation plant at Dartmoor near the South Australian border. This plant uses copper chrome arsenate (CCA) solution as a preservative. This material is highly toxic.

2. CSR reported to EPA on 28 October 1996 that between 25 October 1996 and 28 October 1996 about 6000 litres of a 2.5% solution leaked from an underground tank. The extent of contamination is unknown. The remaining CCA has been removed from the tank.

3. A bore on CSR's premises supplies 40 households 500 metres away with drinking water. EPA informed the local council of the spill and the need to check bore water supplies and advised the Department of Human Services. The Department of Human Services activated DISPLAN. Residents were advised not to drink water from the bore and alternative water supplies were arranged by the Council.

4. The water bore is 80 m deep and in a 90 degree different direction from the expected flow of groundwater at the leak site. The water table is 30 m below the ground.

5. Soil samples around the tank have been taken and groundwater monitoring bores are to be installed to assess the extent of contamination.

6. Installation of bores should commence 4 November 1996.

7. The extent of clean up will depend on the seriousness and extent of contamination - contaminated soil may be removed for off-site disposal and groundwater may need to be pumped to the surface for treatment.

8. EPA has directed CSR to include a test bore between the site of the leak and the drinking water bore, to enable detection of contamination, and to sample the nearby creek to see if it has been contaminated.

9. EPA, the Department of Human Services, CSR and the local council are working together to assess sampling results, determine the ongoing sampling program and assess the potential risk to the public health and the environment.

10. EPA has taken further samples of bore and creek water and is investigating the incident to determine if there have been offences under the Environment Protection Act.

11. Preliminary results of bore water sampling show background levels of Chromium and Arsenic.

12. A meeting of agencies and the company is to be held this afternoon.

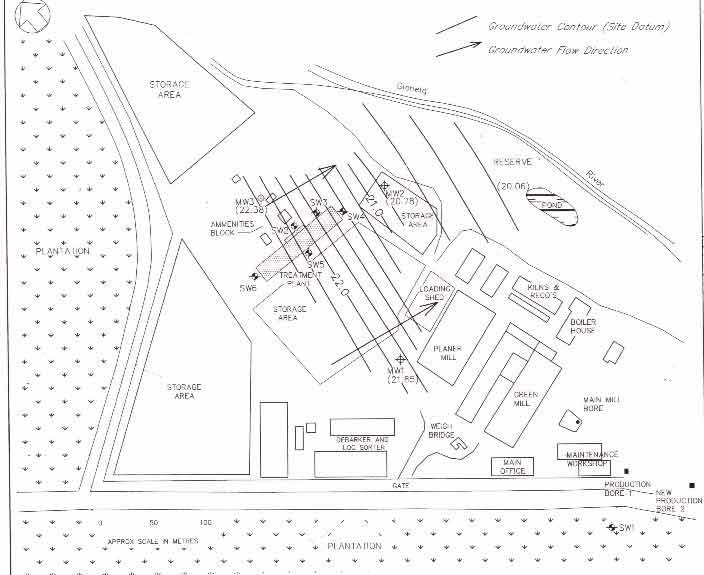

Dartmoor - Victoria. Map of the GTFP sawmill showing direction of groundwater drainage.

8 Nov 1996 - Dartmoor Public Health warning removed.

Recommendations that Dartmoor residents do not use water from the CSR bore, private bores and springs have now been lifted. This decision was reached after a taskforce met in Melbourne today to consider the public health aspects of the copper chrome arsenate (CCA) spill at the CSR Timber Products plant in Dartmoor.

The taskforce included representatives from the EPA, the Department of Human Services (Public Health and Disaster Support and Recovery), State Displan, SES, Glenelg Shire Council, CSR, Woodward Clyde, the State Chemistry Laboratory, and a range of consultants with expertise in ground water issues.

Results of some investigations carried out over the last week have only just become available today. These investigations have shown that groundwater is moving eastwards towards the river and not towards the CSR bore. Therefore contamination of the CSR bore and private bores is extremely unlikely.

However, CSR has started operating a new bore on its site which will provide residents with water tonight. This bore is over 100 metres away from the current CSR bore and further away from the site of the CCA spill.

All testing to date has shown no contamination of groundwater . . . Residents are advised that they may now use water from the CSR and private bores and springs to the south and south-east of the town. This water can be used for drinking, cooking, washing and gardening purposes.

However springs alongside the CSR plant should not be used . . .

Dept of Human Services.

TIMBER TREATMENT COMPANY FINED FOR CHEMICAL SPILLS 24 October 2001

A Bayswater timber treatment company has been fined $30,000 and its director placed on a 12-month good behaviour bond by the Ringwood Magistrates' Court for causing environmental hazard and failing to obtain relevant environmental approvals.

TW Timber Pty Ltd was convicted and fined $12,000 on each of two counts of causing an environmental hazard, and $6,000 for failure to obtain a Works Approval from EPA Victoria before commencing operations at its site.

The company's director, Garrie James, also charged for the Works Approval offence, was placed on a 12-month good behaviour bond. Both the company and Mr James pleaded guilty.

The environmental hazard charges relate to two spills of a copper, chromium and arsenic solution (CCA) from the Bayswater premises last year.

EPA prosecutor, Max Costello, told the court that on 25 May 2000 a mixing tank valve left open overnight caused more than 20,000 litres of CCA to flow from TW Timber's premises into neighbouring factories and the stormwater system, which led to Bungalook Creek. EPA officers discovered that the valve had not been fitted with an automatic cut-off switch and that the factory's bund (spill containment wall) was cracked.

Following the spill, EPA issued a Pollution Abatement Notice to TW Timber requiring the company to fit a cut-off switch and fix the bund to ensure that no waste contaminated waters could leave the site and enter the stormwater system in future.

On 28 August, failure of a pressure valve caused a second discharge of CCA from TW Timber. Staff attempted to clear the discharge by using a fire hose, causing the diluted CCA to again flow off site. The Court was told that, in breach of the

Environment Protection Act, T W Timber had built its treatment plant without a works approval from EPA. A Works Approval for a similar CCA timber plant showed that EPA had required various spill prevention items, such as shut-off valves and proper bunding, to be included in the design.

Speaking after the prosecution, EPA Chairman Dr Brian Robinson said if the company had obtained the relevant works approval from EPA as required, such spills could have been avoided. "It is not enough for companies to clean up after these sorts of incidents. They have a clear responsibility to ensure they do not happen in the first place," he said. "EPA's works approval process exists to ensure that companies have the necessary safeguards in place so that, from day one, their operation is effectively managed from an environmental perspective."

"Industry shares its environment with its local community and, as such, companies have a responsibility to ensure that their operations do not impact adversely on their neighbours. By ignoring EPA's Works Approval process and failing to have appropriate safeguards in place TW Timber had disregarded its obligation to its neighbours," said Dr Robinson.

EPA VICTORIA TAKES ACTION ON CREOSOTE AFTER LORNE INCIDENT 19 December 2000

EPA Victoria will contact foreshore committees across the state to advise them on the use of creosote treatment in waterways, following a recent incident in Lorne's Erskine River. In September EPA started receiving calls from people concerned about a sheen on the Erskine River. The sheen appeared following the installation of creosote-treated boardwalk poles.

EPA south-west regional manager Tony Robinson said that since September EPA officers had inspected and sampled Erskine River regularly. He said the sheen had almost disappeared by December and elevated levels of tar chemicals in the water in October had dropped off substantially by December. Treating timber with creosote prolongs its life and protects it against attack from marine parasites. Creosote is a coal tar derivative that has a black colour and a characteristic smell. Direct contact with the treated timber can cause skin irritations.

Mr Robinson said EPA would work with the Lorne Foreshore Committee of Management and the Department of Human Services to ensure human contact with the creosote-treated pylons was minimised. "EPA will be writing to foreshore committees across Victoria to advise them that they should consider whether creosote treatment is necessary in each application, particularly in estuarine locations," Mr Robinson said. "EPA is also holding discussions with the Australian producer of creosote-treated timbers about overseas best practice guidelines."

Overseas guidelines recommend that timbers undergo post-treatment weathering prior to installation to reduce the amount of creosote remaining on the surface. Although an Australian Standard advises that creosote treatment is suitable for use in Victorian marine waters, EPA warns that failure to take precautions such as weathering before use could result in environmental damage and large penalties under the Environment Protection Act. Mr Robinson said EPA would continue to monitor Erskine River during the coming months. MEDIA ENQUIRIES: Lawana Crimeen, EPA Information Centre Telephone: (03) 9695 2703, 0401 140 862

CSR fined $240,000 over pollution from particleboard plant 26 October, 2001

CSR was today fined $240,000 and ordered to pay $100,000 costs in the Land and Environment Court after pleading guilty to negligently polluting groundwater near Tumut, following a case brought by the NSW Environment Protection Authority (EPA). EPA Director General, Lisa Corbyn, said the court heard how the company discharged the liquid from its industrial process lines to an earth dam known as the `Blue Dam'.

"This water contained toxic chemicals which leaked into the groundwater and then contaminated the spring in an adjoining paddock, making it unsuitable for stock grazing," said Ms Corbyn. "The contaminated groundwater from the Jepsen Avenue factory, also leached into Rifle Range Creek, where it killed aquatic creatures and streamside plants.